Metrics that matter

Powerful data at the right time deliver greater productivity at all levels of the value chain within minutes.

There is no delay in receiving the information. Overall Equipment Effectiveness (OEE) gathers uptime and downtime values, that combine stability and accuracy focusing on reduce costs and increase your productivity.

When operational metrics aren't tuned with company goals, possibilities for conflicts are hudge.

Growing profits is one of the top indicators of company business success. Lowering costs represents considerable challenge for increasing profitability more rapidly than other indicators.

Transparent and complete documentation of all production events meet the challenges and opportunities towards Lean Production in Industry 4.0. Perfectly coordinated, and developed to meet the requirements of EMBEDDED-IIMSS 4.0 production environment.

Comparative key indicator analysis factors such as quality, costs and delivery flexibility determine the value chain in this industry - metrics that matter.

Meet the Experts

Growing profits is one of the top indicators of EMBEDDED-IIMSS 4.0 ongoing business success.

With integrated two-way comprehensive communication solutions company continuously improve efficiency and competitiveness.

To obtain optimization of industrial processes, it is necessary to collect the information, either manually or automatically, to ensure its processing and consolidation into a structured database.

Metrics that you can act on and react within minutes.

EMBEDDED-IIMSS 4.0 gives you the right production decision with the latest HW and SW integration technologies. It shows you the metrics that you can act on and react within minutes. Our process data module is perfect visualisation for maintenance and process optimization in modern production environment.

Key Performance Indicators (KPI's) knows about your production facilities within minutes at the single press of a button.

What metrics actually matter to an operation depends on strategy, industry segment, process type and production and market conditions.

GKISAN.IO EMBEDDED-IIMSS 4.0

Experience matters - Comprehensive Manufacturing IoT Monitoring

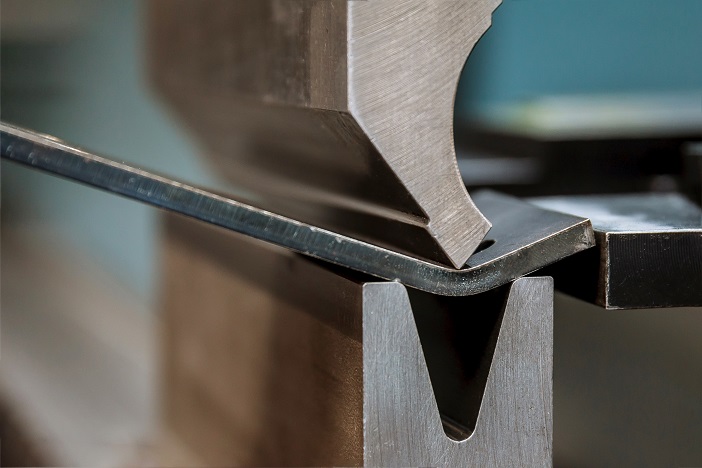

GKISAN.IO introduces EMBEDDED-IIMSS 4.0, comprehensive Industrial IoT Monitoring System Solutions focused on

creating a stable and safe process flow for the industrial presses in Real-time featuring Overall Equipment Efficiency (OEE) Monitoring,

Condition Monitoring, Smart Diagnostics, Power Monitoring and a Track and Trace log system. With a high level of standardization and modular design

EMBEDDED-IIMSS 4.0 ensure short amortisation period, implementation and integration time into automotive industry production.

It is critical to ensure that the enterprise systems respond effectively. There is no delay in receiving the information related to the breakdown event. Get the better view and get the complete information anywhere and anytime. EMBEDDED-IIMSS 4.0 collect and combine data from various sources. With integrated two-way comprehensive communication GKISAN.IO continuously provide a centralized resource from a single sign-on.

Intranet enhances employee and communication, and collaboration by giving people the tools they need to be productive, informed and engaged. EMBEDDED-IIMSS 4.0 helps people work better, anytime, anywhere makes it easy inside an organization to contribute.

Manufacturing Execution Systems (MES): Synchronize factory operations and Business Processes to Monitor the Production Process in Real-Time. From practical experience to practical implementation Real-Time Data Collection display weak points in the production process and directly saves your time and money. Key part is to make the actual work more easier.

It is critical to ensure that the enterprise systems respond effectively. There is no delay in receiving the information related to the breakdown event. Get the better view and get the complete information anywhere and anytime. EMBEDDED-IIMSS 4.0 collect and combine data from various sources. With integrated two-way comprehensive communication GKISAN.IO continuously provide a centralized resource from a single sign-on.

Intranet enhances employee and communication, and collaboration by giving people the tools they need to be productive, informed and engaged. EMBEDDED-IIMSS 4.0 helps people work better, anytime, anywhere makes it easy inside an organization to contribute.

Manufacturing Execution Systems (MES): Synchronize factory operations and Business Processes to Monitor the Production Process in Real-Time. From practical experience to practical implementation Real-Time Data Collection display weak points in the production process and directly saves your time and money. Key part is to make the actual work more easier.

Everyone has a gift for something. Through our EMBEDDED-IIMSS 4.0 we help you discover and develop three-step education system -

the latest training programs you can find.